Why Choose Bestdan for Assembly Services?

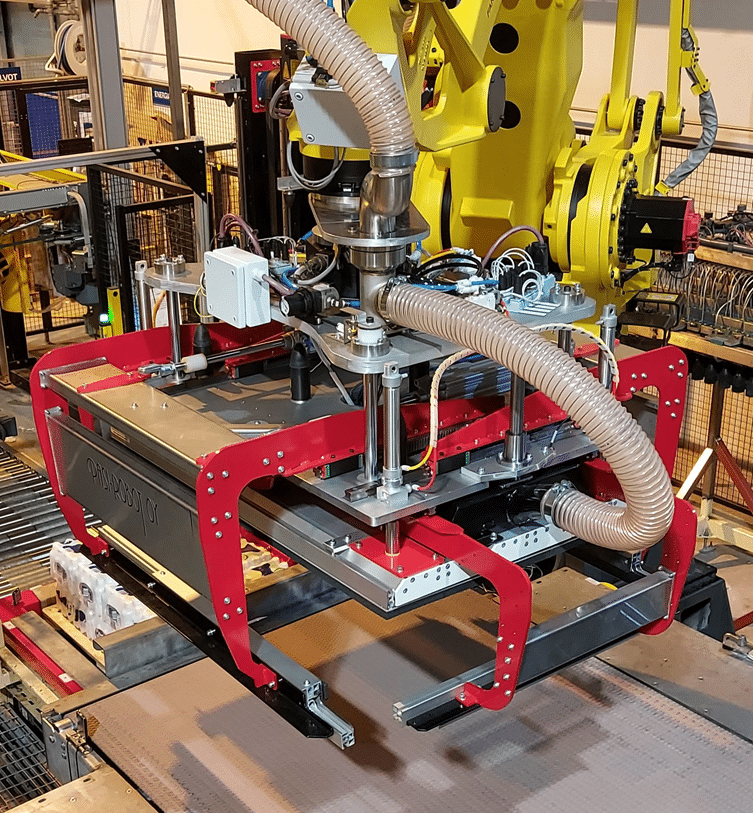

When mechanical design, prototyping, machining, and assembly are all handled under one roof, your project stays cohesive and in professional hands. That’s why our assembly process doesn’t stall when issues arise—we have experienced engineers on-site who can typically identify both the cause and the root cause of a problem, and make real-time adjustments to the process or even to individual parts, always in close collaboration with the client.

Our assembly experience ranges from precision mechanical products to heavy steel structures. Examples include:

- Self-service dispensing machines

- Various locking mechanisms

- Electric saws

- Electronic enclosures

- Different types of prototypes

Thanks to our extensive network, we can also support your full-scale production needs. Whether it’s a small batch or continuous mass production, we’ve got you covered.

Bestdan’s Assembly Services – Tailored to Your Needs

Our assembly services adapt to the specific needs of your business. We can modify our facilities and workflows to meet the requirements of your production. Additionally, we have the capability to design and manufacture any necessary jigs or custom tools to support the assembly process.

With over 25 years of experience in the industry, we have built strong relationships with subcontractors both in Finland and internationally. This means we can also assist in sourcing various components as needed.

All assembly work at Bestdan is carried out by skilled professionals. Thanks to our experience, we’re able to identify potential assembly challenges early on and address them efficiently. Our operations are flexible and can be adjusted to fit your project schedule. In short, our assembly service is shaped around your needs.

Why choose us?

Wide-ranging skills

We have extensive experience in various manufacturing techniques to support our design work – and in-house production capabilities as well.

Read more about us