What is mechanical design?

Mechanical design is the process of developing mechanical devices, structures, and components for various applications. It is essential for the designer to understand all manufacturing methods and know how to combine them appropriately, taking into account the estimated production volumes and manufacturing efficiency.

The design process must consider multiple factors, such as forces, environmental conditions, and manufacturability, to ensure that the final result is both durable and functional. One of the most critical stages is prototyping and testing, as it allows validation and improvement of the product’s performance before final production.

Get in touch with the professionals at Bestdan, and let’s start mechanical design together! High-quality mechanical design is key to successful product development.

Mechanical design for projects of all sizes

Mechanical design and prototype manufacturing delivered flexibly and cost-effectively for all types of clients — from private individuals to publicly listed companies, and from small tasks lasting just a few hours to large-scale projects spanning several years.

Bestdan engineering agency designs and delivers high-quality mechanical solutions tailored to its clients’ needs.

Our in-house prototype workshop and manufacturing capabilities allow us to test the functionality of solutions quickly and cost-effectively — already in the early stages of development, rather than waiting until the design is nearly complete. Many of our clients value this hands-on approach, where potential mechanical risks are addressed through early physical testing.

Having our own prototype workshop brings flexibility and efficiency to projects, ensuring a smooth and responsive product development process. Mechanical design is most effective when supported by a well-equipped protoshop and high-quality tools.

Mechanical Design at Bestdan – Our Approach

Mechanical design at Bestdan is all about comprehensive customer support, problem-solving, and collaboration. Our designers bring decades of experience across a wide range of projects, manufacturing methods, and production environments—enabling us to approach each project with a broad, solution-oriented mindset. We also consider the needs of all project stakeholders, ensuring a truly holistic service. For example, our years of experience in assembling hospital equipment have given us a deep understanding not only of traditional DFM (Design for Manufacturing) and DFA (Design for Assembly), but also of DFV (Design for Validation).

We’re easy to work with and highly flexible. We listen to our clients and recognize their needs, which allows us to seamlessly adapt to their processes—or take the lead when needed. Our typical way of working is in close cooperation with the client. This keeps the work purposeful and ensures fast and efficient feedback loops. Mechanical design, to us, is a true collaboration with the customer.

Examples of products we have designed

Bestdan is a mechanical design professional with extensive experience in a wide range of machines and devices we have designed over the years. For us, mechanical design is a craft — one in which we have broad expertise across various industries.

In recent years, we have designed, for example:

- Turnkey industrial production equipment

- Medical devices and sample collection instruments

- Dental chairs and related equipment

- Tow trucks

- Stage technology such as wire hoists and movable floor structures

- Product testers

- Design prototypes and styling models

- Lifting aids

- Various types of locks

- Maintenance systems

- Different chemical industry reactors

- Injection-molded parts

- Production jigs

- Heavy-duty steel structures such as maintenance platforms

- Products for the defense industry

Mechanical design delivered flexibly and with a customer-friendly approach

Our extensive experience, well-equipped prototype workshop, and broad network of partners provide seamless support for our mechanical design work. Our operations are highly flexible, allowing us to serve clients of all sizes — from small-scale tasks to large, complex projects.

We build long-term client relationships, and thanks to close collaboration, we become deeply familiar with our clients’ needs and requirements. Whenever possible, the same designer manages the project throughout the entire partnership, ensuring continuity and trust. The role of our experienced specialists often goes beyond design — they also act as a vital link between product development and production.

We design and produce all of the previously mentioned products, and much more, both as one-offs and in series. In short, Bestdan has hands-on experience in mechanical design across virtually every industry.

When is mechanical design needed?

Mechanical design becomes relevant in nearly any product development or improvement project. Roughly half of Bestdan’s assignments are related to industrial production equipment or auxiliary tools, while the other half involves the design of serially manufactured devices.

Well-executed mechanical design is an investment that pays itself back many times over during a product’s lifecycle. In addition to functionality, product and mechanical design significantly influence manufacturing costs — and a well-designed product typically enjoys a longer lifespan as a result.

Mechanical design is connected to almost everything you can physically touch. It’s not just about gears and machines — it also involves form and usability, production equipment, material flow systems, and enclosures for electronic devices. For example, when you drink a bottle of soda, not only the drink but also the packaging — as well as the machines used for filling, gripping, and measuring — have all been carefully designed and manufactured.

In short, mechanical design is everywhere – embedded in nearly everything we do.

The most common stages of mechanical design

The process is adjusted as needed based on the client’s and project’s requirements, but in some form, the following stages are typically included in a mechanical design project:

-

Requirements specification – defining the key features and performance expectations of the product

-

Ideation and concept design – exploring possible solutions and selecting the most feasible approaches

-

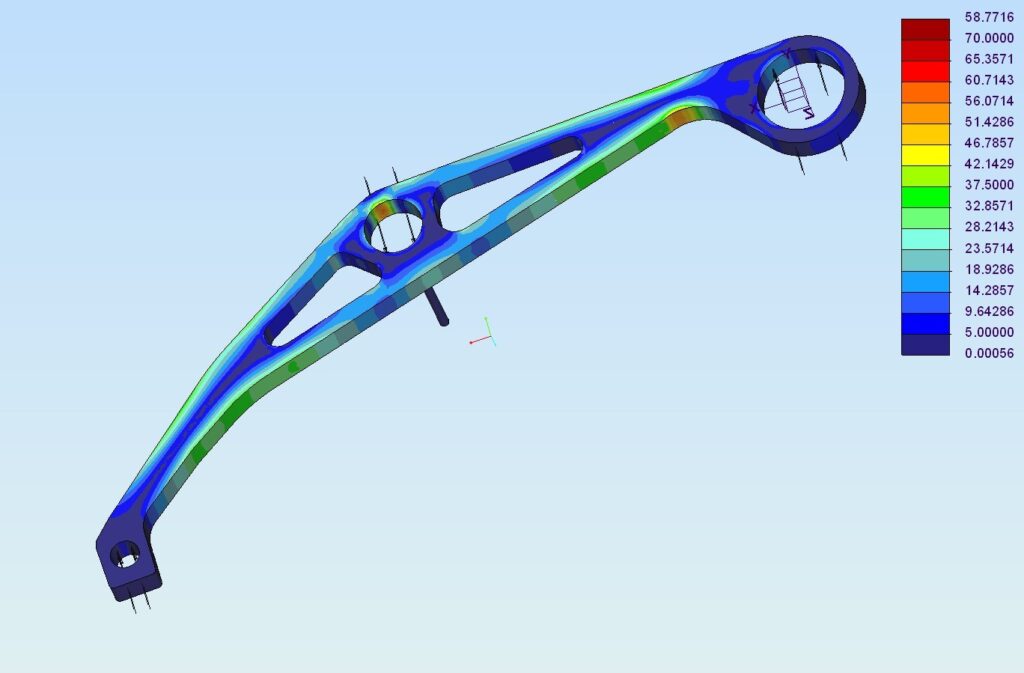

Actual design work – 3D modeling, structural analysis, 2D drawings, and preparation of manufacturing data

-

Prototypes and testing – building and testing sample units, then refining the design based on test results

-

Production ramp-up and product launch

-

Lifecycle management – improvements, updates, and maintenance of design data over time

Modern manufacturing techniques

At Bestdan, high-quality product design starts with having the best professionals, modern manufacturing techniques, and a strong focus on delivering top-tier results. In product development and design, it’s essential to consider a wide range of factors to ensure the final product works as a cohesive whole.

Common manufacturing techniques we work with:

- Machining

- Sheet metal fabrication

- Injection molding

- Die casting

- Rotational molding

- Blow molding

- Vacuum forming

- Profile design

- 3D printing

Over the years, we have built a broad network of trusted partners. This allows us to offer not only our own in-house engineers, mechanical designers, and project managers, but also expertise in electronics design, industrial design, and mass production of components. We also have the experience and capability to take a product all the way from idea to market.

For example, we’ve successfully developed and commercialized a power tool that started as nothing more than an idea — and has since been sold in over 30 countries.

Mechanical design driven by production requirements

Production needs play a central role in mechanical design, as this approach ensures not only the technical functionality of the product but also its manufacturability and cost-effectiveness. A skilled mechanical designer understands that even the smallest design decisions can significantly impact the manufacturing process, timelines, and ultimately the final cost of the product. That’s why it is critical to carry out the design work in line with production requirements.

To achieve this, mechanical design must take into account the practical realities of manufacturing — primarily by utilizing existing production methods and tools, and by avoiding unnecessary complexity that could drive up costs. In practice, this means applying principles such as modular design, using simple and standardized components, and optimizing material selection with the manufacturing process in mind.

An experienced mechanical designer with deep knowledge of production processes is a valuable asset to any company. They can proactively identify potential problem areas and develop creative solutions that ensure the product’s success in the market — while also maintaining production efficiency.

Ultimately, mechanical design aligned with production enables smooth collaboration between design and manufacturing teams, resulting in products with competitive pricing and quality — and a measurable positive impact on the client’s business.